By: David Putnam, Owner of Jabar Corporation; Terry Cox, Manager of West Ouachita Sewer District #5; D. M. Griffin, Jr., PhD, P.E. – Formerly Professor of Civil Engineering, Louisiana Tech University

Infiltration and inflow have long been a problem in aging wastewater collection systems. This case study revisits this issue, taking into account infiltration around manhole covers as well as through pick and vent holes.

Definitions for Infiltration and Inflow

Infiltration is usually defined as the unintentional introduction of groundwater into a gravity sewer line as a result of various types of cracks and other defects generally occurring below the ground surface.

- Cracked or broken joints, commonly occur in rigid pipe as a result of improper bedding

- Separated joints resulting from vibration

- Crushed pipe occurring as a result of excessive loading

- Root intrusion

- Flow into manholes as a result of leakage around manhole covers (a topic not considered until now)

Inflow is usually defined as the intentional (at the time) introduction of storm water into a gravity sewer line by activities or events acceptable at the time.

- Flow through pick holes in manhole covers during rainfall events

- The intentional discharge of storm water from roof drains into a sanitary sewer line, which is a common occurrence in older portions gravity sewer systems.

In this paper, we examine the effect of reducing infiltration and inflow through pick and vent holes and around manhole covers and how this affects pump run time in selected pump stations. The study area is in Ouachita Sewer District #5 shown in Figure 1, below. All pump stations in the study area tributary to the Kiroli Pump Station which pumps to the Ouachita Parish treatment plant.

Leakage Through/Around Manhole Covers

While leakage through pick holes in manhole covers has been recognized as a significant source of inflow, leakage between the cover and the supporting surface has not. A report by Meyer and Warren entitled “A Report on Inflow of Surface Water through Manhole Covers” examined the quantity of leakage through vent holes, open pick holes, and the space between the cover and the bearing surface concluding that significant leakage occurs depending on the head on the manhole cover, the area of flow provided by pick and vent holes, and the seal between the cover and bearing surface.

Study Location

In an attempt to quantify the volume of inflow through manhole covers, a yearlong study was conducted in Ouachita Sewer District #5, located in Ouachita Parish, Louisiana in northeast Louisiana. These stations are shown in Figure 2, below. They are Hart, Canyon, Nichols, Nichols Lane, T. Johns, and Restful Homes.

Manholes tributary to six other pump stations in the area were not sealed. These are shown below in Figure 3. The pump stations in both groups were equipped to measure the run time of the pump(s). Pump run times for each group of pump stations were recorded in 2013, prior to sealing manholes and in 2015 after sealing the manholes in the “Kiroli” group of pump stations.

Sealing Manhole Covers

New manhole covers were obtained for all manholes tributary to pump stations where the pump run times were being monitored. The new covers had no pick or vent holes. Each cover was outfitted with a proprietary device called a “Sewer Sentry” developed by David Putnam, owner of Jabar Corporation, an Underground Utilities Contractor specializing in sewer repair and rehabilitation, located in Calhoun, Louisiana. The device is shown below in Figure 4 and installed in Figure 5. It is constructed of Dupont Zytel, which is a nylon resin that is:

- Impact resistant

- Chemical resistant

- UV light resistant

- Heat resistant

- Cold resistant

In addition, all manholes were fitted with a 1” wide, 1/8” rubber seal to minimize leakage between the cover and bearing surface. The Sewer Sentry was installed through a hole drilled in the cover using the rubber gasket to minimize leakage. The Sewer Sentry protrudes approximately 5/8 of an inch above the surface of the manhole cover thus allowing some sheet flow over the cover without leakage but not so high as to damage bicycles, vehicles etc. The hole allows for the escape of gases which would otherwise build up in the sewer system creating an explosive hazard.

Precipitation

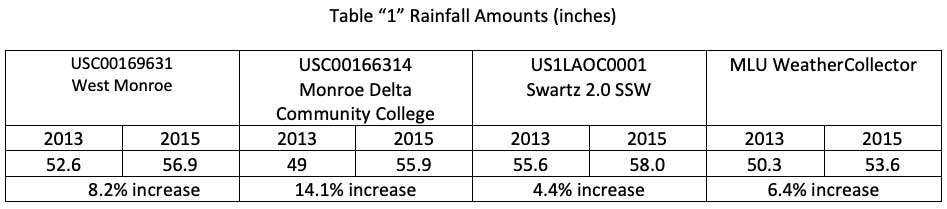

Annual precipitation values were obtained as the average of 3 NWS weather stations and the web site, “Weather Collector” (http://www.theweathercollector.com/) and shown below in Table 1.

The average increase in precipitation for the 4 stations was 8.3 % between 2013 and 2015.

Pump Run Times

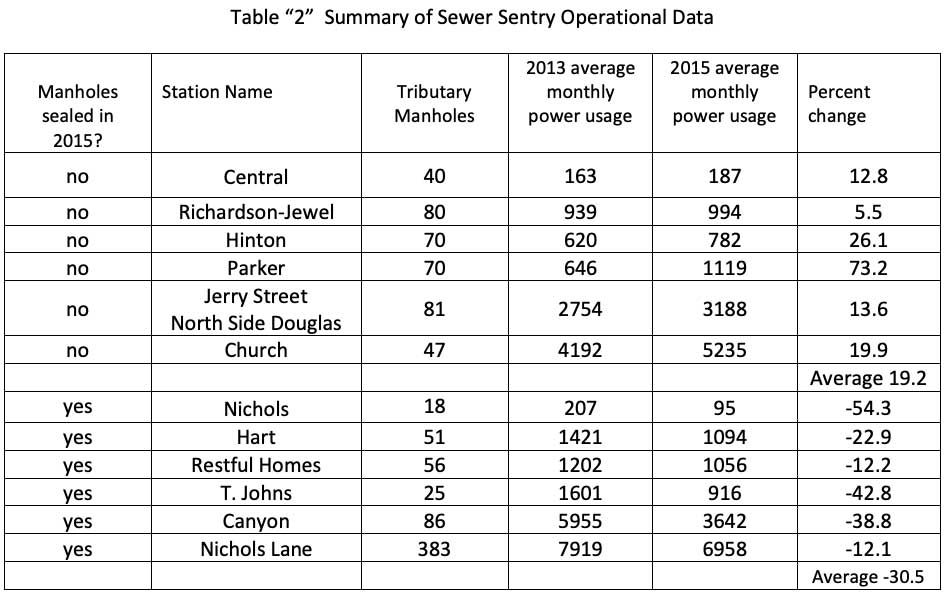

Table 2 below shows the effect of sealing manhole covers on pump run times. Both sets of manhole covers (hereafter referred to as the Church group and the Kiroli group) were unsealed in 2013 while the 7 stations terminating with the Kiroli pump station were sealed in 2015. It appears that sealing the manhole covers made a substantial difference in run times between the two groups. The run times in the Church group increased an average of 19.2% per month with a range of between 5.5% and 42.3%. All six stations in the group showed an increase. Given that precipitation increased by 8.3% between 2013 and 2015 this is not unexpected. However, all 7 stations in the Kiroli group registered a decrease in run times between 2013 and 2015. The average run time dropped 26.7% with a range between 3.5% and 54.3%.

In an attempt to quantify the effect of sealing manhole covers it might be useful to examine a simplified cost model. Since we have the monthly Kw-hr usage, we can compute the cost to run each station assuming a cost per Kw-hr of $0.099, obtained from documents published by Entergy. The results are shown in Table 3 below. The cost to operate the Church group of pump stations increased from $11,045.20 in 2013 to $13,667.90 in 2015, an increase of 23.7%. The cost to operate the Kiroli group of pump stations decreased from $21,745 in 2013 to $16,348 in 2015, a drop of nearly 25% even though the annual precipitation increased by 8.3%.

Summary

This study suggests that removal of pick and vent holes, sealing the region between the cover and the bearing surface and installation of the Sewer Sentry incorporating a raised vent hole to allow for minimal inflow and manhole ventilation can result is substantial reduction in pump run times and a corresponding drop in power costs. The Church group of pump stations saw an average increase in cost of 23% between 2013 and 2015. The increase in precipitation between 2013 and 2015 was 8.3%. All six (6) pump stations in the group saw an increase in cost ranging from 13 to 76%. In contrast, the Kiroli group of pump stations saw an average drop in power cost of 24.8% between 2013 and 2015 with all six (6) stations seeing a drop ranging for 12 to 54%.

Conclusions

- Use of the Sewer Sentry as well as eliminating pick holes and sealing the bearing surface appears to dramatically reduce infiltration and inflow as evidenced by pump run times and the associated cost.

- Use of the Sewer Sentry allows sewer gases to be vented to the atmosphere while minimizing inflow, thus avoiding potentially explosive conditions in gravity sewer systems.

References

- Memo dated January 13, 2011 from Entergy Corporation entitled: “Continued Low Entergy Prices for Entergy Louisiana; Customers Still Encouraged to Conserve”

- Sewer Sentry dramatically reduces I/I and corrosive gases, Sewer Sentry, https://sewersentry.com/

About the Authors

David Putnam, owner JABAR Corporation, Utility Contractor, Calhoun, LA

Terry Cox, Ouachita Parish Sewer District #5, Ouachita Parish, Louisiana

D.M. Griffin Jr., PhD, P.E. – retired Professor of Civil Engineering, Louisiana Tech University, Ruston, LA